Zinc die casting

Zinc Die Casting - NO Minimal Order Quantity

Compared to the other casting materials, zinc is perhaps the most accessible and versatile metal you can use in the die casting process. Zinc alloy has good properties not only in toughness but also the high impact strength. With zinc die casting, you can create various metal parts and components with certain finishing qualities and particular mechanical and physical characteristics.

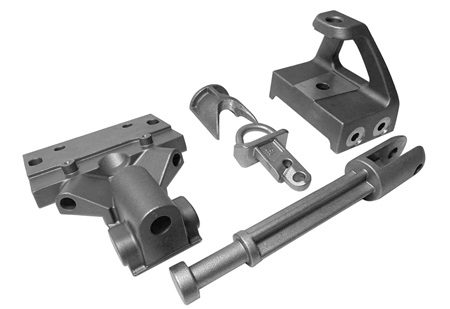

Since zinc alloy for die casting parts performs much better than any other sand-casting metal parts in toughness and impact strength at average temperature, the parts are widely used in many industries. As one of the best alternatives to aluminum, manufacturers use zinc die cast to produce certain metal parts, prototypes, and components for various applications. However, the most common use of zinc die casting is in the automotive industry.

You can find many parts and components in the automotive industry that use zinc alloy die casting in their production processes, such as vehicle brakes, engines, air conditioner components, and many others.

● Engines.

Zinc has excellent thermal and electrical conductivity, which is why zinc alloy die casting parts manufacturers use zinc alloy casting to produce parts of vehicle engines in the automotive industry. It is durable and will last for a long time.

● Air Conditioning Parts.

Some parts of air conditioning systems in various vehicles use high-pressure zinc die casting in their production process. Zinc is an excellent material for creating small parts and components for the vehicle’s air conditioning system.

● Fuel Systems.

The good electrical and thermal conductivity also makes zinc suitable for the vehicle’s fuel systems. Many components used in the vehicle’s fuel systems are produced in zinc under a zinc die-casting plant.

● Chassis Hardware Parts.

The durability of zinc materials makes it suitable for chassis hardware parts production. Zinc die cast is the primary method to produce various chassis hardware parts in vehicles.

● Brakes and Power Steering.

The durability of zinc materials is also helpful for producing parts and components for the brakes and power steering in vehicles. It will ensure long-lasting use of the vehicle’s brakes and steering mechanisms.

What Is Zinc Die Cast and How It Works

Zinc alloy casting works the same way as the die casting method with other metals. However, with the low melting point of zinc materials, the die casting process can go faster than with other metals. First, you will need to prepare the zinc alloy die casting mold to produce the parts or components. The Zamak die-casting mold will have two pieces clamped together using the high-pressure mechanical system.

Next, you will need to melt the zinc materials and insert the melted zinc into the mold cavities. The melted zinc will solidify, following the hollow shapes of the mold cavities. Once it thickens, you can pull out the resulting metal parts or components from the clamped mold shell and use it for other production processes.

The Characteristics of Zinc Alloy for Die Casting

Zinc materials have specific characteristics that make them suitable for die casting. With the unique attributes of zinc materials, manufacturers can produce high-quality hardware parts and components for various purposes.

● Stability.

Zinc has a material stability that allows you to produce zinc parts and components that are sturdy and durable.

● Thermal Conductivity.

Zinc is an excellent material that can withstand high operating temperatures, allowing you to create parts that need to get exposed to constant heat.

● Electrical Conductivity.

It is also typical for manufacturers of zinc alloy die casting parts to use zinc to produce various electrical components, as it has excellent electrical conductivity.

● Low Melting Point.

Zinc materials have a low melting point, so casting is easy and allows you to produce parts at a faster production rate.

● Electroplating.

The zinc die casting plant can apply electroplating on die-cast zinc materials, making it more conductive to electricity. It is perfect for mechanical components that require constant electric currents.

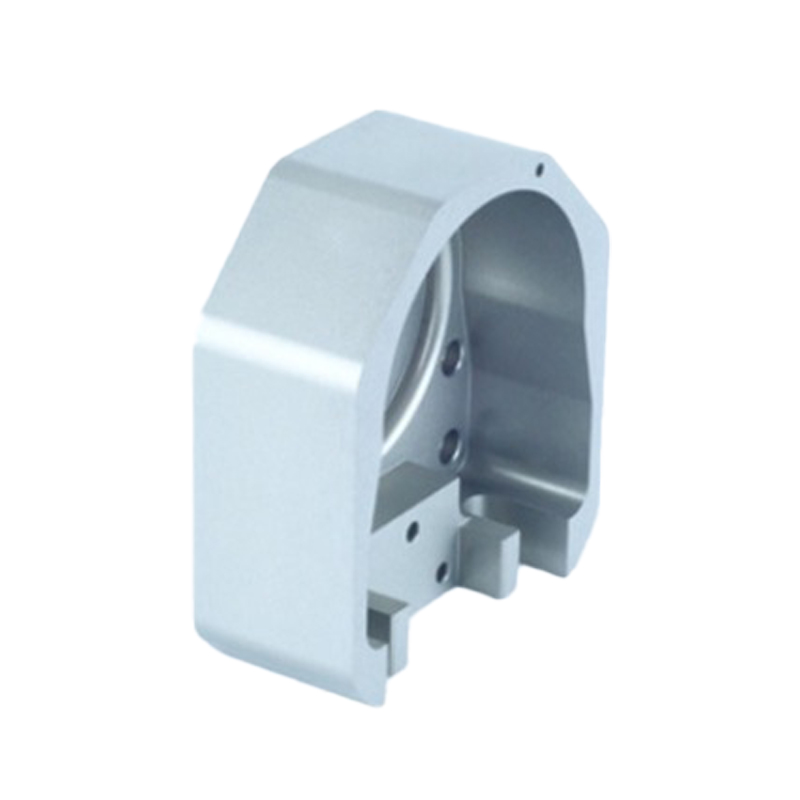

● Complex Geometries.

The zinc die casting companies can also use zinc to create complex geometries, allowing you to produce parts and components with complex design requirements.

FENGYE’s Zinc Die Casting Alloy

Zinc alloy die casting is one of the core services of FENGYE. We offer a range of die-cast zinc alloys to meet our customers' die-casting needs. Zinc2, Zinc3 and Zinc5 are the most popular zinc alloy die casting materials in recent years. The properties and properties of these three grades of zinc are different. Here we have the details:

Zinc alloy die casting

Zinc 2

Also known as Zamak 2, it has the highest hardness and strength of any zinc alloy.

Zinc 3

Also known as Zamak 3, it is the most commonly used zinc alloy for TEAM Rapid and has excellent performance in terms of finishing characteristics.

zinc5

Also named Zamak 5. It is less flexible than Zinc 3, but has higher strength due to its higher copper content. Zinc 5 is commonly used in Europe.

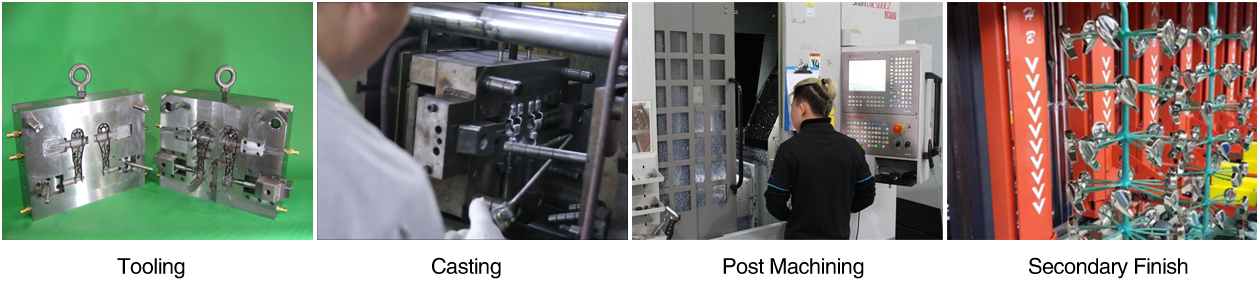

China zinc die casting manufacturer

As one of the best zinc alloy die casting manufacturers in China, FENGYE provides one-stop manufacturing services for zinc die castings. We offer services from engineering design to zinc alloy die-cast mold manufacturing, zinc injection molding, post-processing and secondary finishing. We can provide customers with high-quality zinc parts in varying volumes from a few grams to over 50 pounds. We also offer low-volume, rapid manufacturing of zinc parts through our casting services.

work clothes

Single-cavity molds, multi-cavity molds, series molds, etc., zinc alloy die-casting molds can be provided. MUD formwork for small batch zinc castings.

casting

They produce zinc castings from small clips to large electronic devices with complex geometries such as thin walls.

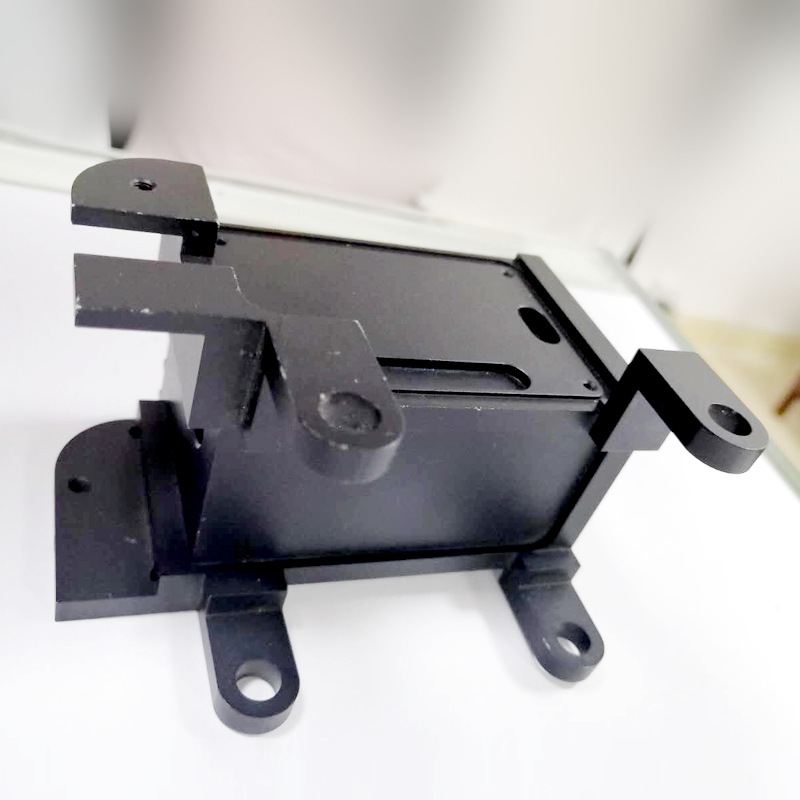

post processing

Equipped with advanced CNC machining centers, we can perform CNC post-machining on tight tolerance dimensions to obtain specific parts.

Secondary finishing

Powder coating, e-coating, chrome and other gloss/matte finishes.

Benefits of Zinc Die Casting

Zinc materials can offer various benefits for the manufacturers of zinc alloy die casting parts in their production process. For instance, zinc is much more cost-effective than other popular metal alloys for die castings, such as aluminum and magnesium. It can also provide the manufacturers with even faster production cycles, as this metal is straightforward to cast.

● Fast Production with Cost Effectiveness.

Zinc has material characteristics that allow you to cast it quickly so that you can complete the die casting process of zinc materials much faster than any other metals. Also, zinc is much more affordable than aluminum or magnesium, which can be a suitable alternative if you want to cut costs in production while still keeping quite a good production quality.

● Finishing Options.

You can use various finishing options for zinc pressure die casting, including mirror-polish, matte, and patina finish. It will allow you to improve how the hardware parts or components look and give the end products some additional properties.

● Accuracy and Precision.

The zinc die casting plant can accurately and precisely perform the die casting process on the design. You can use this metal to complete complex design requirements for your project with no problem. Provide specific qualities and characteristics that make it suitable for certain production schemes.

● Great Durability for Long-Term Use.

Zinc die casting companies can also rely on zinc material for its durability for long-term use. The metal parts or components in zinc will have sturdy and durable characteristics, which make it last for a long time.

Low Volume Zinc Die Casting Parts

FENGYE offers aluminum and zinc die casting services to meet the needs of small batch production. We use three main methods in small batch manufacturing to reduce your mold costs and obtain high quality castings. These methods are:

MUD mold holder (main unit mold)

MUD mold, we also call the main unit mold, whether it is aluminum die casting or zinc die casting project can use MUD mold. It is a fast interchangeable modular die holder for small batch manufacturing. Two or more casting molds share a MUD mold holder to reduce costs and lead times. TEAM Rapid has MUD mold holder; We created a series of MUD templates and stored and prepared them for the upcoming project. They are free and free of charge.

Home mold

Due to the need for small batches, we can create a mold with multiple cavities to cover multiple parts of the same material with similar dimensions. We can obtain different zinc alloys for die casting in one cycle. Integrated molding can not only significantly save mold costs, but also save casting costs. It is often used in injection molding and die casting. Part layout is crucial!

Interchangeable blades

One of our customers wanted to have 3 versions of a zinc die cast. The three versions have the same outline and different knot methods, but require a lower volume. 100 parts after sample approval. As a professional zinc die casting plant, TEAM Rapid recommends that customers continue to adopt the interchangeable blade solution. We made a mold with three different sets of inserts. All of these inserts vary in geometry and can be quickly and easily assembled into a mold. After casting a version, we remove the mold to replace the insert.

Contact FENGYE for Zinc Die Casting Services

If you need to know how to choose zinc die castings and aluminum for your project, FENGYE can provide OEM services. Please send your quote document immediately to manager@rfidbrf.com. Our sales engineers will give you a quotation as soon as possible.

Previous: Aluminum die casting

Next: Hydraulic stamping