Aluminum die casting

Aluminum Die Castings - Leading Aluminum Die Castings Manufacturer

Aluminum die casting is a manufacturing process that has been around for decades and has different applications in various industries. It helps to keep the overall product lightweight while ensuring that hardware parts and components are durable and can be used for a long time. You can find applications for die-cast aluminum in consumer electronics, network equipment, the automotive industry, the aerospace industry, home appliances, and more.

With aluminum die casting, die casting manufacturers can also produce small batches of products that need to meet specific weight requirements. In addition, with its high heat resistance characteristics, aluminum die casting can enable hardware parts or components to operate at high temperatures.

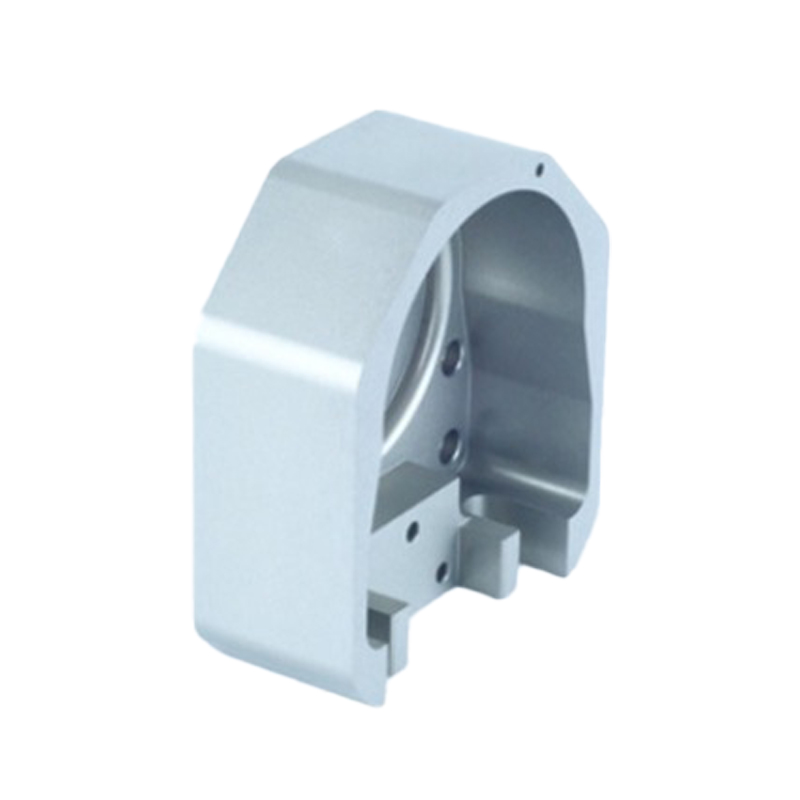

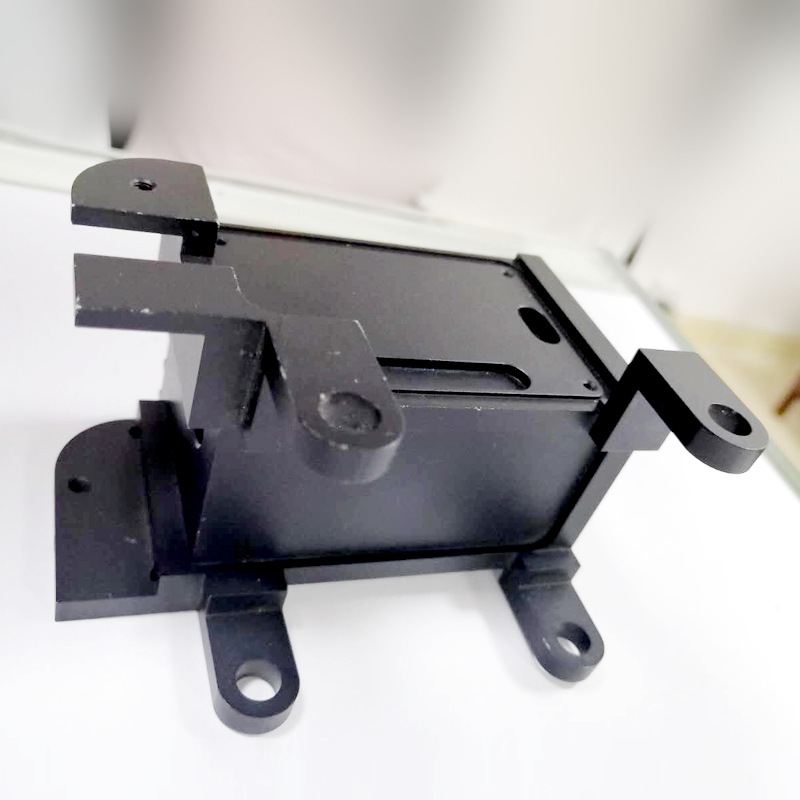

The most significant advantage of aluminum die casting is that it can produce lighter parts and has more options for surface finishing than other die casting alloys. Aluminum can maintain high dimensional stability in thin walls. It is versatile and corrosion-resistant. In addition, aluminum can withstand the highest operating temperatures of any die-cast alloy. It can be used in almost any industry. As a professional die casting manufacturer, TEAM Rapid has decades of experience in producing all types of aluminum die casting, including aluminum housings and covers; Aluminum brackets and plates; Aluminum radiator; Aluminum valve body; Aluminum gearbox housing, etc

How aluminum die castings work

Aluminum die casting is not significantly different from any other die casting method. It uses die-cast aluminum alloy as the main material for the process. Its working steps are simple.

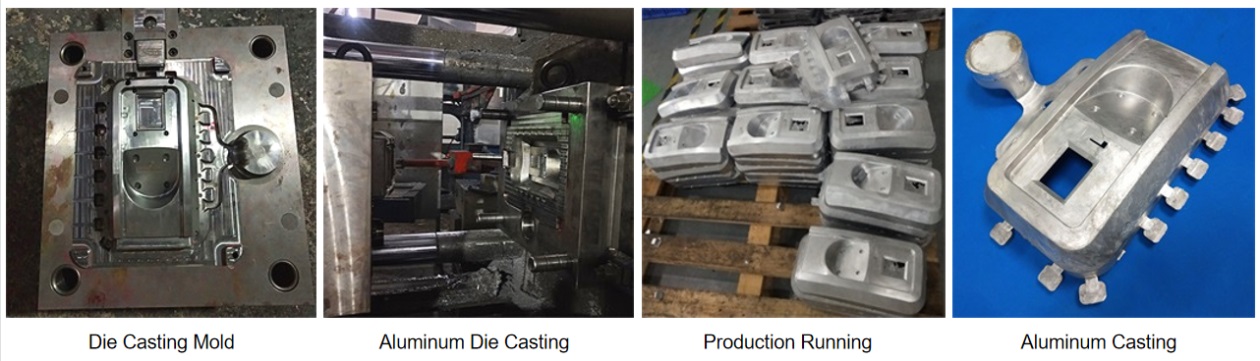

First, you need to prepare a steel mold for the specific hardware part, assembly, or prototype you want to produce. The steel mold requires a cavity and core sides that are clamped together to form the entire shape of the aluminum die-cast part you are making. You then need to prepare the die-cast aluminum of your choice, melt it, and pour it into the mold cavity. Afterwards, the molten aluminum will solidify inside the mold.

The die-casting aluminum process is completed. You can then open the clamping housing of the steel mold and remove the aluminum part you produced, which you can use in a subsequent rapid manufacturing process. Depending on the complexity of the shape, you may need to create a unique mechanism for your custom aluminum die-cast mold to produce the hardware part of your intended design.

Fengye's aluminum die-cast alloy

Fengye is a professional aluminum die-casting manufacturer in China. Our aluminum die castings serve a wide range of industries. In the past ten years, we have manufactured a series of motor housings, die-cast radiators, exhaust fans, aluminum casings, die-cast aluminum cookware, washing machine handles, camera housings, LED housings, etc. ADC12 and A380 die cast aluminum are TEAM Rapid’s most popular die cast aluminum alloys.

Storage of die-cast aluminum alloy

Aluminum Alloy Casting Alloy - Die Cast Aluminum ADC12

ADC12 (Al-Si-Cu based cast aluminum alloy) has good castability and high mechanical properties. These alloys are often used in complex automotive parts such as transmissions, cylinder blocks, converter housings, etc. It is also one of the most widely used metal choices in many die-cast housings produced internationally.

Die Cast Aluminum Alloy - Die Cast Aluminum A380

A380 die-cast aluminum is one of the most commonly used die-cast aluminum alloys. Thanks to its good performance, the A380 is widely used in many applications.

It has the best combination of mechanical, casting and thermal properties.

It has pressure sealing properties, excellent fluidity and thermal crack resistance.

It is widely used in a variety of products including die-cast aluminum radiators, engine mounts, electronic equipment cases, home furniture, die-cast aluminum cookware, transmission cases, hand tools, etc.

The Benefits of Aluminum Die Casting

Compared to other die casting materials, aluminum die cast can offer various benefits to the manufacturers, such as producing lighter and more durable hardware parts and components. Die cast aluminum is also suitable for a wide range of applications, as there are various aluminum alloys you can use for multiple purposes.

● Lightweight and Durable Materials.

Aluminum is a lightweight and durable material to use, which is perfect for a wide range of applications across various industries. Using aluminum die casting parts, you can keep the product at a minimum weight while maintaining its durability for long-term use.

● Various Alloy Options.

You can choose between various alloy options depending on the parts or components you want to create. Each die casting aluminum alloy has its characteristics, pros, and cons.

● Polished Surface Finishes.

Aluminum die cast materials will provide you with polished surface finishes when you use them in the die casting process. Also, you can choose from among various finishing options available.

● High Operating Temperature.Aluminum is a die casting material that can withstand high operating temperatures. You can use it to produce hardware parts or die cast aluminum heat sinks that operate at high temperatures, such as those in the combustion engine. You don’t need to worry that the functions or components will break if you use aluminum as the primary die casting material.

● Corrosion Resistance.

Aluminum is also corrosion resistant, allowing you to use the die cast aluminum parts or components for a long time without worrying about the details getting rusted or corroded.

Fengye’s die-casting aluminum process

Aluminum casting and die casting are efficient and economical processes for producing aluminum metal parts. As a professional aluminum die-casting manufacturer, Fengye can utilize this superior manufacturing technology to produce aluminum parts of various shapes and undercuts.

Custom aluminum die casting mold

The aluminum casting process first requires a steel mold. We also call these reusable steel molds molds. They can be designed to produce complex shapes and geometries with high precision and repeatability. Mold life can vary from 10,000 to 100,000+ cycles, depending primarily on the mold steel.

Aluminum die casting process

The mold is installed into the die casting machine. Molten aluminum is then injected into the mold under high pressure. Once the molten die-cast aluminum solidifies, the mold is opened and the casting is removed from the mold. The mold is then closed and the process begins again. The cycle time of the aluminum die casting process depends on the weight and size of the part. Generally, the larger the part, the longer the cycle time. Contact us today for aluminum die castings!

Aluminum die casting manufacturer

Feng Ye is one of the best aluminum die casting companies in China. We provide quality aluminum die casting services to meet your project development. From hundreds of prototypes to thousands of production parts, we offer our customers mold and casting solutions. We have been in aluminum die casting for decades, serving a wide range of customers in different industries around the world. Nearly 99% of our customers are satisfied with our service and quality. Moreover, they are satisfied with our price.

High mixing low volume supply chain aluminum castings

1. As a professional aluminum die casting supplier, FENGYE provides customers with turnkey solutions integrating prototyping, mold, die casting, machining, surface finish and assembly, even for small batch aluminum die casting.

2. FENGYE offers a wide range of aluminum materials (ADC12 and die-cast alloy a380) to meet your small batch manufacturing needs.

3. Even for small batch aluminum die castings, FENGYE follows strict quality control.

4. FENGYE offers a range of secondary processing options to meet your product needs.

5.FENGYE is close to Hong Kong. Your aluminum castings can be exported easily and quickly through the port of Hong Kong.

Aluminum pulley die-cast housing - cast aluminum and cast aluminum die-cast

Get started on your next aluminum die casting project

Zinc die casting vs aluminum die casting? Need aluminum die castings manufactured in small batches and post-processed? FENGYE is one of the best aluminum die casting companies. We're pretty sure we can help you. Please contact us today at manager@rfidbrf.com. Here, we offer one-stop manufacturing services for your aluminum die casting needs!

Previous: No More

Next: Hydraulic stamping